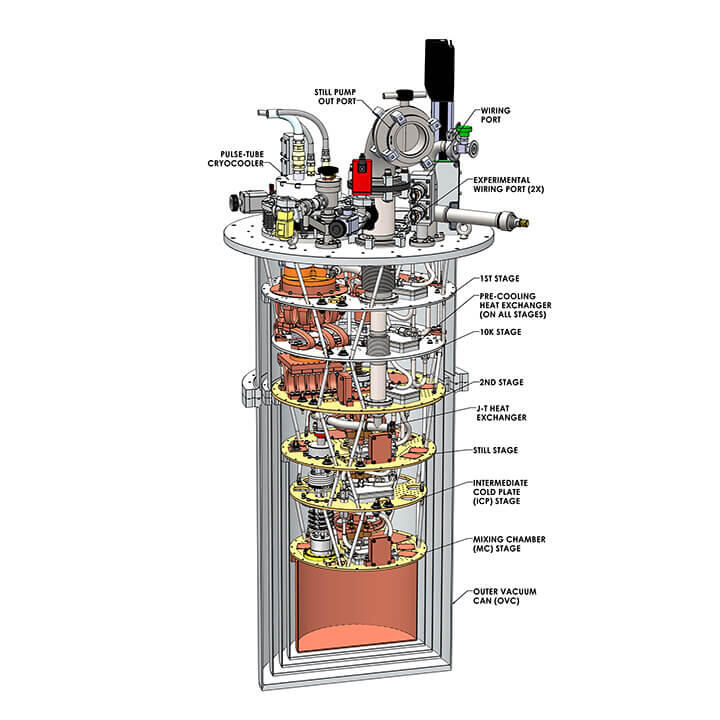

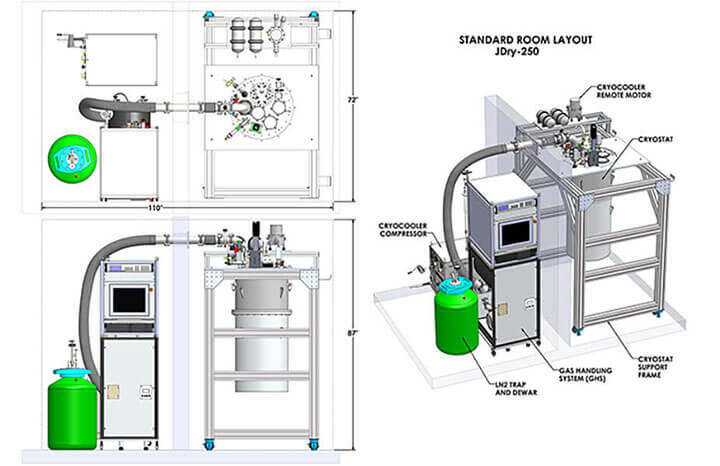

FormFactor - HPD JDry-250 - Cryogen-free Dilution Refrigerator

-

Low running costs, less vibration, less noise, reduced maintenance

-

Large convenient experimental access: Up to 12 line-of-sight ISO100 ports located on perimeter of plates

-

CMN calibrated thermometry on MC plate

-

Operation via touch panel controller: Remote operation via ethernet interface

FormFactor’s JDry cryogen-free dilution refrigerators enable easy and cost-effective cooling to temperatures below 10 mK. The JDry models have been optimized for quantum computing applications and can accommodate up to 270 semirigid cables. General-purpose configurations and astronomy/detector cooling are also provided.

The JDry cryogen-free dilution refrigerator series includes multiple standard models. All are available with easy push-button cooling using the robust and fully-automated NI LabVIEW™-based “JACoB” gas-handling system (GHS).

The JDry-250 model is fitted with a cold-plate of 305 mm (12″) diameter, and provides a cooling power of more than 250 µW at 100 mK.

More Product Information

Customized Solutions for a Variety of Challenging Applications

We are your partner for challenging applications. Our comprehensive technical and application know-how over all probe system platforms and our expertise for customized products is based on an extensive experience over many years. We offer a special demo support in-house or at the customer, as well as after sales support for complicated setups.

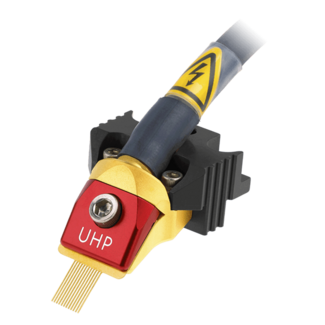

- Customizable configuration up to 25 contacts: RF, Eye-Pass power, ground, logic

- Lithographically-defined tips allow automated over temperature measurement on pads as small as 30 µm x 50 µm

- Low and repeatable contact resistance on aluminum pads (< 0.05 Ω) ensures accurate results

- Durable probe structure ensures more than 250,000 contacts

- Able to measure from -40°C to +125°C without compromising performance or accuracy of specifications

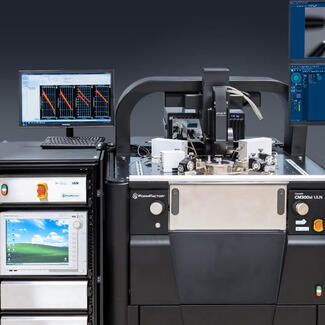

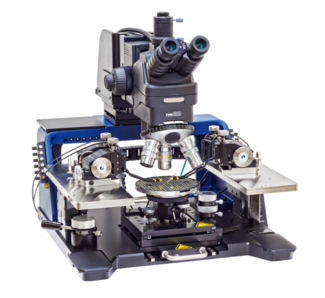

Comprehensive, Turn-key Integrated Measurement System (IMS) with Keysight A-LFNA for On-wafer R&D Advanced Low-Frequency Noise Measurements

- Power bypass inductance: 8 nH

- Standard DCQ probes have flat tip needles available in nickel-plated tungsten or BeCu with diameters of 0.75 mil, 1.0 mil and 1.5 mil.

- Supports collinear and non-standard needle configurations

- Up to 16 DC for standard; maximum of 24 DC for custom

- Ideal for probing the entire circuit for functional test

- DC probes can provide power or slow logic to circuit under test

Flexibility

- DC, AC and RF/microwave device characterization, 1/f, WLR, FA and design debug

- Full thermal range of -60°C to +300°C

- Compatible with TopHat or IceShield

- Usage of manual and motorized positioners, probe cards within EMI-shielded environment

- Upgrade path to meet your future needs

- Stable and repeatable measurements over a wide thermal range

High accuracy and repeatability

- Reliable and repeatable contact

- Moisture-free, light-tight and EMI-shielded test environment with MicroChamber® technology

- Advanced EMI-shielding with PureLine and AttoGuard technologies available

- Superior low-leakage and low-noise measurements

- Safe and accurate hands-off testing

- Minimizes settling times for efficient measurements over full thermal range

See "Specifications & Details" tab for more key features

-

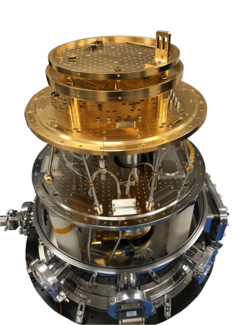

Fully isolated experiment space for true 4K temperatures during probing

-

Cryogenic positioners to provide large travel ranges without warming up the device

-

Flexible thermal jumpers to ensure high thermal conductance and low mechanical transmission

-

A soft vacuum bellows provides a compliant mounting interface for the cryocooler

-

Quick release vacuum feedthroughs for easy configurability

-

A large rectangular port for high signal capacity

-

Enables coaxial measurements up to 10,000 V and 300 A pulsed (600 A in a parallel configuration) with a single touchdown

-

Even distribution of high current with innovative multi-fingertip design

-

Compatible with TESLA 200/300 mm power device characterization system

-

Reduced measurement time by testing both high-voltage and high-current conditions with a single touchdown

-

Accurate characterization of a wide range of pad sizes and test currents, with minimum pad damage and contact resistance

-

Safe, reliable and repeatable high-current/voltage measurements over a wide temperature range (from -55°C to +300°C)

Flexibility

- Ideal for a wide range of applications such as RF, mm-Wave and sub-THz characterization, FA, DWC, MEMS, optoelectronic tests and WL

- Re-configurable and upgradable as requirements grow

- Minimizes setup times with no loss in performance or accuracy

- Seamless integration of various measurement instruments

Stability

- Solid station frame

- Built-in vibration-isolation solution for superior vibration attenuation

- Rigid microscope bridge

- Compact and rigid mechanical design

- Highly accurate measurement results

- Incorporates best-known methods

Ease of Use

- Ergonomic and straightforward design for comfortable and easy operation

- Low-profile design

- Simple microscope operation

- Quick and ergonomic change of DUT through pull-out stage

- Minimize training efforts

- Fast time to data

- Convenient operation

-

Load-lock chamber: Cycle devices 10X faster in a cryogenic environment

-

High-density electrical interface at cryogenic temperatures: More pins on the device enables more test structures to be probed with a single cooldown

-

Base temperature of < 2K or < 4K with high cooling power: Test devices at the temperatures that matter most for pre- screening and evaluating device performance

-

Low vibration: Stable contact with the device under test and enables low noise measurements

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.

Contact Details

FormFactor, Inc. Corporate Headquarters

7005 Southfront Road, Livermore, CA 94551, USA

Phone: 925-290-4000

Test & Measurement